THE OPPORTUNITY

PS&S was selected to design the State-of-the-Art cGMP manufacturing facility for radio-ligand therapy and potentially alpha-emitting radio-ligand products. The overall objective was to design the expansion of manufacturing capacity in the United States for radioactive injectable cancer treatment products. The facility is designed for an initial accommodation of production lines with provisions for a complete building out and the future building expansion. The project was a green field site specifically designed for the personnel and process flow of the facility and maximizing the footprint of the building.

THE CHALLENGE

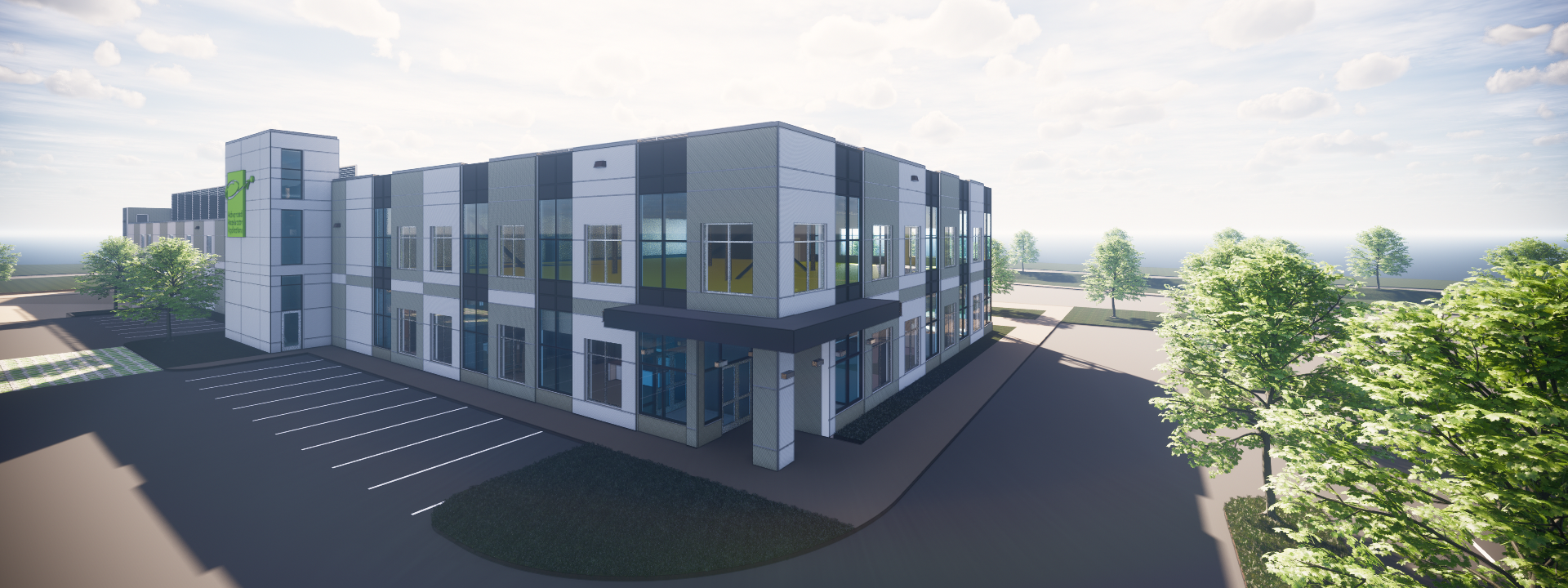

The program included a 16.7-acre site, zoned in a special commercial manufacturing zone and located within an industrial park. The building square footage of 70,000sf maximum included 20,000sf of two-story office building and 50,000sf of expandable cGMP manufacturing. The office space was designed for open office collaborative workspace with meeting rooms, and conference rooms doubling as a tornado shelter, breakroom, records retention, Health & Safety wellness area and a lobby. The manufacturing space includes locker rooms, gowning spaces, clean room manufacturing, packaging, waste accumulation, warehousing and shipping/receiving loading docks. The clean room areas (Grade C & D) included raw material staging and kitting, manual compounding/filling lines, automated compounding/filling lines, visual inspection, sterility testing, QA/QC microbiology labs, packaging, cGMP storage, waste storage, sample retention and shipping/receiving.

THE PS&S SOLUTION

PS&S were the architects and engineers of record for the complete facility design and construction oversite. Our Architects and Structural engineers designed an aesthetically pleasing façade of insulated precast and curtain wall panels. Our Engineers designed a robust infrastructure of validated redundant HVAC, compressed air and water systems. Non-validated equipment included redundant and expandable chiller plant, cooling towers, boilers, geothermal pumps, fire protection wet & clean agent systems, plumbing domestic and laboratory waste and gas systems, electrical service, double ended substation with two primary utility feeds, UPS both rotary and battery systems and generator back-up. Additionally, control systems for fire alarm, building automation systems (BAS), validated (EMS), access control and surveillance systems.