THE OPPORTUNITY

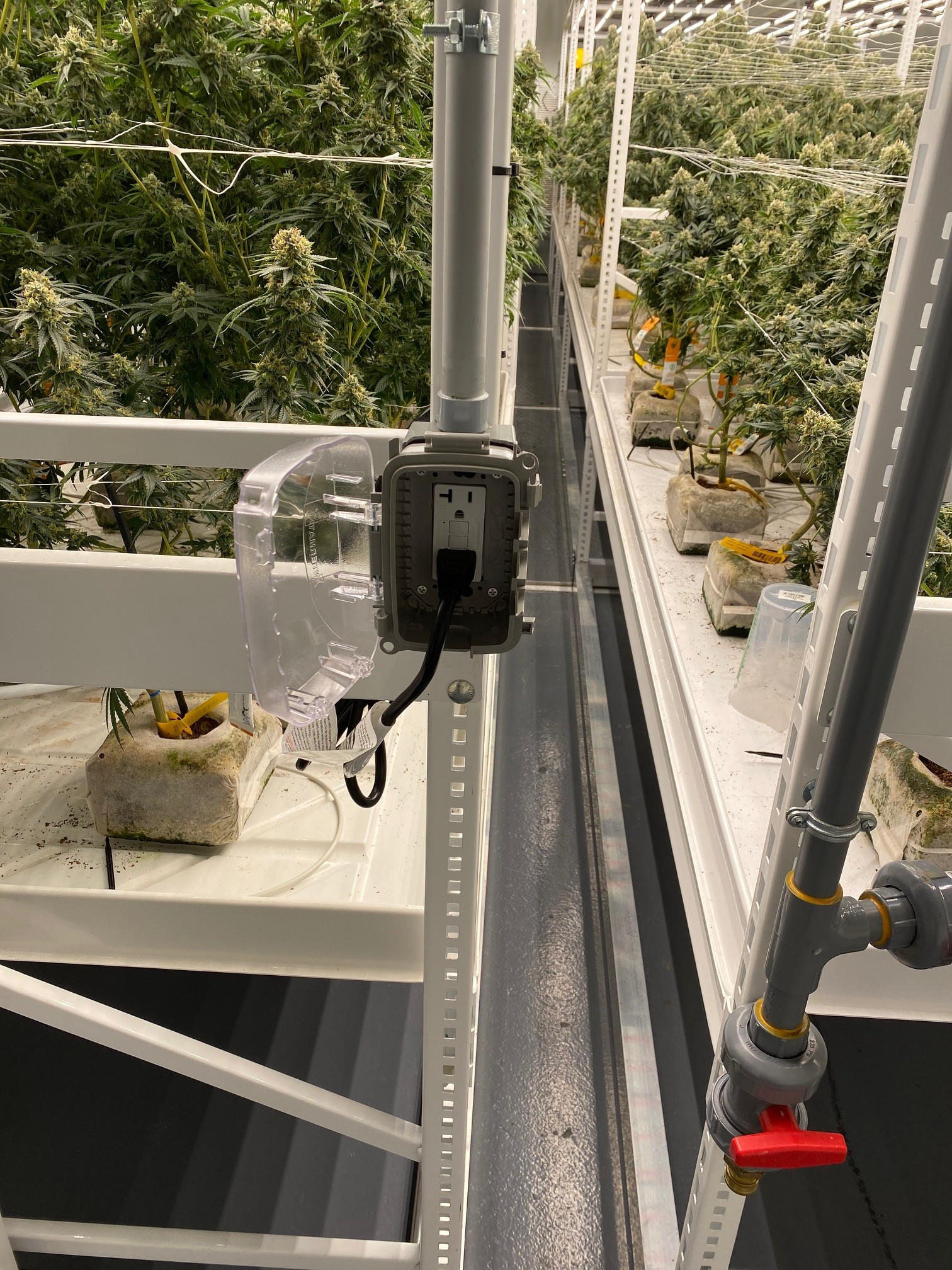

The client requested PS&S to design the renovation of a 71,000 square foot facility to house their cannabis growth production. The facility is being used for the production of medical cannabis in the forms of flower, oils, and confections. The production process includes mother, clone, propagation, vegetation, flower, dry, trim, post processing and extraction.

THE PS&S SOLUTION

The design was done in 3 phases and is currently on going in construction.

Phase 1: Initial flower development utilizing premanufactured grow pods for mother, vegetation, and flower production, supplemented by dry, trim, and packaging facilities

Phase 2: Increased flower development utilizing industry standard grow facilities: mother, vegetation, flower, dry, trim, post processing facilities

Phase 3: Further increasing of production areas; clone, mother, vegetation, flower, dry, extraction laboratory and post processing facilities

The systems supporting the facility includes, Plumbing RO water generation, fertigation systems, CO2 integration, HVAC systems, humidification and dehumidification systems, electrical power, lighting, security, and emergency generator systems.