THE PS&S SOLUTION

PS&S provided architectural and engineering services on a fast-tracked basis for a new biotech support services facility. The new facility will provide central media and buffer preparation, sterilization, and filling. The facility will also provide central container washing and sterilization for vaccine manufacturing support. PS&S provided design services for process, mechanical, electrical, civil, structural, and geotechnical engineering of the manufacturing services building.

The facility is designed in accordance with EU (European Union) clean room design guidelines and includes containment and isolation design details appropriate for a validatable cGMP manufacturing facility.

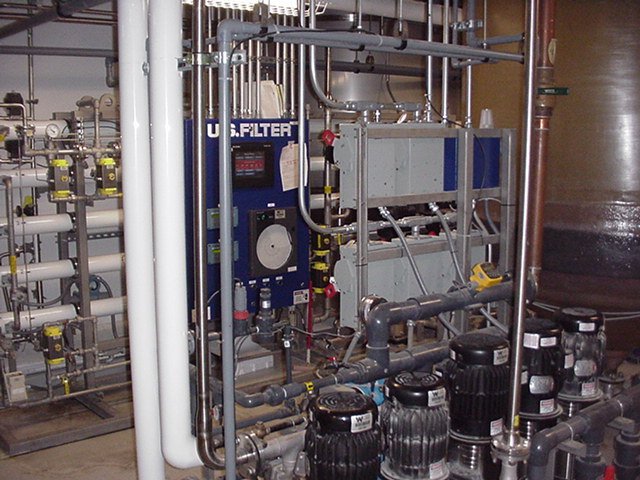

PS&S designed and built a two tier WFI generation and distribution system to provide WFI to users on two floors. The system consists of a Vapor Recompression Still that is designed to produce 14 GPM of WFI. There are two 6000-gallon steam-jacketed tanks, one for each distribution loop, each with its own sanitary circulation pump. A third 500-gallon tank provides WFI for a Clean Steam generator. Each circulation loop is instrumented to closely monitor water quality. Alarms are annunciated on the buildings central utilities panel (BMS).

The building meets both cGMP and EU standards for sterile processing facilities.

The facility was fast-tracked in coordination with the construction management firm engaged by the owner.